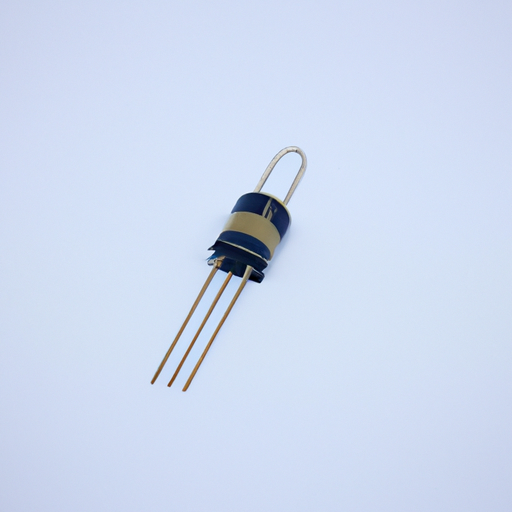

Film resistors are one of the most commonly used types of resistors in electronic circuits. They are widely used in a variety of applications, from simple LED circuits to complex audio amplifiers. Film resistors are known for their stability, accuracy, and reliability, making them a popular choice among engineers and hobbyists alike.

There are several popular models of film resistors that are commonly used in electronic circuits. Some of the most popular models include:

1. Metal Film Resistors: Metal film resistors are one of the most common types of film resistors used in electronic circuits. They are made by depositing a thin film of metal, usually nickel-chromium or tantalum nitride, onto a ceramic substrate. Metal film resistors are known for their high precision and stability, making them ideal for applications that require accurate resistance values.

2. Carbon Film Resistors: Carbon film resistors are another popular type of film resistor that is commonly used in electronic circuits. They are made by depositing a thin film of carbon onto a ceramic substrate. Carbon film resistors are known for their low cost and wide range of resistance values, making them a popular choice for general-purpose applications.

3. Thick Film Resistors: Thick film resistors are made by depositing a thick film of resistive material, usually a mixture of metal oxides, onto a ceramic substrate. Thick film resistors are known for their high power handling capabilities and are often used in high-power applications such as power supplies and motor control circuits.

4. Thin Film Resistors: Thin film resistors are made by depositing a very thin film of resistive material, usually a metal alloy, onto a ceramic substrate. Thin film resistors are known for their high precision and stability, making them ideal for applications that require accurate resistance values.

5. Metal Oxide Film Resistors: Metal oxide film resistors are made by depositing a thin film of metal oxide onto a ceramic substrate. Metal oxide film resistors are known for their high power handling capabilities and are often used in high-power applications such as power supplies and motor control circuits.

6. Fusible Film Resistors: Fusible film resistors are designed to fail in a safe manner when subjected to excessive current or power. They are often used in applications where safety is a concern, such as in automotive circuits and power supplies.

Overall, film resistors are a versatile and reliable component that is used in a wide range of electronic circuits. Whether you are building a simple LED circuit or a complex audio amplifier, film resistors are sure to be a key component in your design. With their stability, accuracy, and reliability, film resistors are a popular choice among engineers and hobbyists alike.